JAN 27, 2023

Additive Manufacturing for Supply Chain Strategy and Sustainment

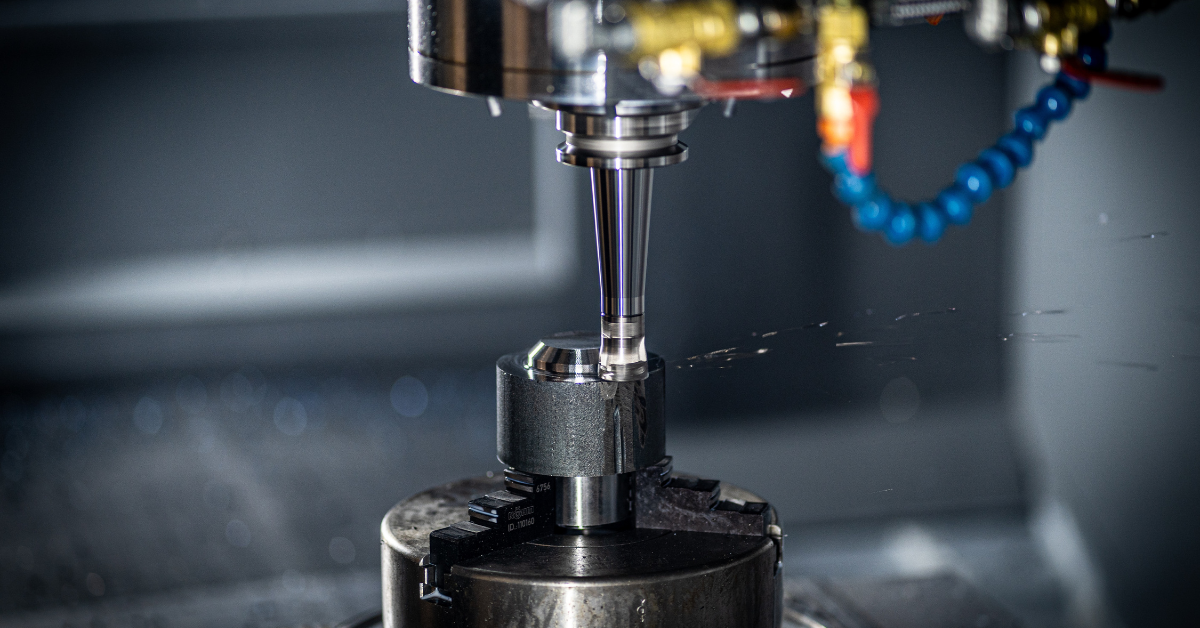

Recent breakthroughs in additive manufacturing (AM)— the process of creating an object by joining materials to make parts from 3D model data, usually one layer at a time—are shedding new light on ways the Department of Defense (DoD) can enable innovation and modernization of defense systems, support readiness and enhance warfighter readiness.

Led by Drs. Dan DeLaurentis and Jitesh Panchal of Purdue University, the Acquisition Innovation Research Center (AIRC) is supporting the adoption of an additive manufacturing supply chain strategy in military departments by developing a decision support tool. This “Decision Engine” provides users, such as DoD decision makers, with an algorithmic view of the variables to make an optimized decision regarding where and how additive manufacturing can have the most impact.

“Additive manufacturing is becoming increasingly popular in sustainment-related decisions,” says Panchal. “When parts break, they need to be replaced. Additive manufacturing allows us to make one-off parts that can be built in the field or on a ship, which makes it easier for the DoD to manufacture replacement parts as needed, as opposed to keeping an inventory of all the parts that might fail in the service.”

The Decision Engine was demonstrated using three use cases. Use case one, aircraft fleet maintenance using additive manufacturing, found a correlation between the cost of utilizing additive manufacturing, the penalty associated with mission delays, and the use of additive manufacturing. The second, a spacecraft application used the Decision Engine to demonstrate how it could be integrated into the mission engineering process of designing and manufacturing satellite components. The third use case compared the use of several manufacturing approaches to produce small batches of custom aircraft components. Two scenarios were analyzed: one that recreated the original component design and material across manufacturing processes, and another that explored topology optimization.

“We wanted to create a framework, which allows us to integrate different decisions into a consistent, single tool related to additive manufacturing,” said Panchal. “It could be an engineer who is trying to figure out what’s the best machine for printing a part. What’s the best material combination? How does the choice of material affect the outcome? And then there are the high-level decisions about how to acquire and procure developing technologies.”

Taking a holistic approach to the design of the Decision Engine, Panchal employed the use of a digital engineering strategy to ensure that all the complex information—various aspects of CAD models, manufacturing process parameters— was collected in a way that can be made available to the appropriate decision makers. “All the information that is required to make a part is collected in digital format,” he says. “Because of the nature of this technology, I think it’s more feasible to use additive manufacturing in the entire digital engineering chain as opposed to traditional processes.”

The data feeding the Decision Engine was primarily informed by openly available data sources and prior projects the team had worked on. But in the future, when it is to be utilized in the field, the decisions will be supported by a variety of data sources, like open databases, proprietary databases developed by manufacturers and data aggregators that have collected information from manufacturers. And the specific data related to parts and materials will depend on the application under consideration.

Further possibilities for operationalizing the Decision Engine include connecting it to the additive manufacturing database at Virginia Tech and applying additive manufacturing to crisis management within the DoD.

Click below to read the executive summary and full report of this research.